ABB自動化在加拿大的高級技術顧問Klaus Kacy, 參加了4月底在CIM’s Montreal總部舉行的慶祝活動,并接受獎項授予。

從波蘭格利維策科技大學取得控制工程碩士學位的Klaus說:“這是一個真正的榮譽,因為其是McParland獎歷史上的第一次授予給提供者的獎。”

他在加拿大領導了優秀的礦用提升機技術中心,可在加拿大幫助實現成功的提升機修補,美國和墨西哥從第一次到達加拿大,即1987年開始就從事于海上工作。

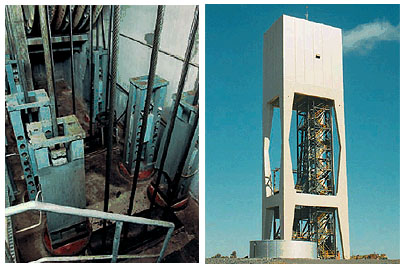

提升機是采礦操作的基礎,他們在運載礦石、操作人員和設備時必須是安全可靠的,因為通常是在地下作業。

現代礦用提升機的系統非常復雜,它要求詳細的設備知識,如控制工程和電氣、汽力和水力系統。這樣的知識寬度是北美小組成功的基礎。

在加拿大,Klaus在魁北克北部的礦井中開發升降機系統,此礦井有2,250米升(北半球最深處為7380英尺)。但這并不是世界上最深的,最深的礦是南非的East Rand金礦,3,500多米升(超過11,000英尺)

Klaus從事他的職業生涯是從1968年一個領班做起的,兩年后,成立了一個自動化中心,從事礦石拋光,聚集了50多名工程師和技師。隨后,他開始開發新控制系統,主要開發礦用升降機。

他在1979年去了尼日利亞,在Kaduna Polytechnic教學,在1982年在南非加入Asea,在那里組建了礦用提升機小組。小組開發了獨一的升降系統。

擁有30多個專利

他開發的礦用系統遍及世界,39年的研發工作及專業經驗,使得他創造了30多項專利。

他說:每一個提升機都不相同,ABB的責任就是將我們的設備和系統應用在不同的機械組件中,以及把不同的升降機應用在電氣設備中。

由于現代提升機系統極其復雜,協作是非常重要的。Klaus補充到:我為我們的小組感到自豪。幾乎我們所有的工程師都是由我聘請和培訓的,在我和我的客戶看來他們在北美是最棒的隊伍。

ABB相關新聞

—ABB喜獲3.5億美元訂單連接英荷高壓電網

—ABB喜獲7,000萬美元訂單為Delhi鐵路提供電力設備

—ABB推出新型高壓斷路器

—ABB贏得5千4百萬美元合同

original text

original text

[COLOR=#708090]

ABB mining specialist wins gold prize in Canada

2007-05-25 - An ABB specialist in hoist technology has won the prestigious Donald J. McParland Memorial Medal from the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) for outstanding engineering achievements and service to the mining industry.

Klaus Kacy, a senior technical consultant with ABB Automation in Canada, accepted the award at a gala event at CIM’s Montreal headquarters at the end of April.

"This is a real honor, because it’s the first time in the history of the McParland award that it has been presented to a supplier," said Klaus, who holds a MSc degree in control engineering from Gliwice Technical University in Poland.

He leads the center of excellence for mine hoist technology in Canada, and can point to scores of successful mine hoist revamps in Canada, the United States and Mexico since he first arrived in Canada working for Asea in 1987.

Hoists are essential to mining operations. They must be safe and reliable to carry tons of ore, people and equipment in and out of the mines, and often reaching startling depths underground.

Modern mine hoists are complex systems which require detailed knowledge of drives, control engineering and also electrical, pneumatic and hydraulic systems. Such breadth of knowledge is the basis of the North American team’s success.

In Canada, Klaus was influential in developing the hoist systems for a mine in Northern Quebec that is 2,250 meters deep (7,380 feet – the deepest shaft in Northern Hemisphere). That is by no means the deepest in the world - the East Rand gold mine in South Africa is more than 3,500 meters deep (more than 11,000 feet).

Klaus began his career as a foreman in a coal mine in Poland in 1968, and after two years set up an automation centre for Polish coal mines which grew to employ more than 50 qualified engineers and technicians. Later, he began developing new control systems, principally for mine hoists.

He moved to Nigeria in 1979 to teach at Kaduna Polytechnic, then joined Asea in South Africa in 1982 and established a mine hoist team. That team developed unique hoist systems that were later adopted throughout ABB.

More than 30 patents

He has developed systems for mines all over the world, and in 39 years of professional experience his R&D work has resulted in more than than 30 patents.

"Every hoist is different," he said, "and ABB’s strength is knowing how to adapt our equipment and systems to the different mechanical and electrical requirements of different hoists."

Teamwork is essential in view of extremely complex modern hoisting systems, Klaus added. "I am very proud of our mining team. Almost all of our mine hoist engineers were either hired or trained by me, and in my opinion and the opinion of our customers, it is the best team in North America."[/COLOR]

聲明:本文為中國傳動網獨家稿件。未經許可,請勿轉載.

—ABB喜獲7,000萬美元訂單為Delhi鐵路提供電力設備

—ABB喜獲7,000萬美元訂單為Delhi鐵路提供電力設備  —ABB推出新型高壓斷路器

—ABB推出新型高壓斷路器  —ABB贏得5千4百萬美元合同

—ABB贏得5千4百萬美元合同  original text

[COLOR=#708090]ABB mining specialist wins gold prize in Canada

2007-05-25 - An ABB specialist in hoist technology has won the prestigious Donald J. McParland Memorial Medal from the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) for outstanding engineering achievements and service to the mining industry.

Klaus Kacy, a senior technical consultant with ABB Automation in Canada, accepted the award at a gala event at CIM’s Montreal headquarters at the end of April.

"This is a real honor, because it’s the first time in the history of the McParland award that it has been presented to a supplier," said Klaus, who holds a MSc degree in control engineering from Gliwice Technical University in Poland.

He leads the center of excellence for mine hoist technology in Canada, and can point to scores of successful mine hoist revamps in Canada, the United States and Mexico since he first arrived in Canada working for Asea in 1987.

Hoists are essential to mining operations. They must be safe and reliable to carry tons of ore, people and equipment in and out of the mines, and often reaching startling depths underground.

Modern mine hoists are complex systems which require detailed knowledge of drives, control engineering and also electrical, pneumatic and hydraulic systems. Such breadth of knowledge is the basis of the North American team’s success.

In Canada, Klaus was influential in developing the hoist systems for a mine in Northern Quebec that is 2,250 meters deep (7,380 feet – the deepest shaft in Northern Hemisphere). That is by no means the deepest in the world - the East Rand gold mine in South Africa is more than 3,500 meters deep (more than 11,000 feet).

Klaus began his career as a foreman in a coal mine in Poland in 1968, and after two years set up an automation centre for Polish coal mines which grew to employ more than 50 qualified engineers and technicians. Later, he began developing new control systems, principally for mine hoists.

He moved to Nigeria in 1979 to teach at Kaduna Polytechnic, then joined Asea in South Africa in 1982 and established a mine hoist team. That team developed unique hoist systems that were later adopted throughout ABB.

More than 30 patents

He has developed systems for mines all over the world, and in 39 years of professional experience his R&D work has resulted in more than than 30 patents.

"Every hoist is different," he said, "and ABB’s strength is knowing how to adapt our equipment and systems to the different mechanical and electrical requirements of different hoists."

Teamwork is essential in view of extremely complex modern hoisting systems, Klaus added. "I am very proud of our mining team. Almost all of our mine hoist engineers were either hired or trained by me, and in my opinion and the opinion of our customers, it is the best team in North America."[/COLOR]

original text

[COLOR=#708090]ABB mining specialist wins gold prize in Canada

2007-05-25 - An ABB specialist in hoist technology has won the prestigious Donald J. McParland Memorial Medal from the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) for outstanding engineering achievements and service to the mining industry.

Klaus Kacy, a senior technical consultant with ABB Automation in Canada, accepted the award at a gala event at CIM’s Montreal headquarters at the end of April.

"This is a real honor, because it’s the first time in the history of the McParland award that it has been presented to a supplier," said Klaus, who holds a MSc degree in control engineering from Gliwice Technical University in Poland.

He leads the center of excellence for mine hoist technology in Canada, and can point to scores of successful mine hoist revamps in Canada, the United States and Mexico since he first arrived in Canada working for Asea in 1987.

Hoists are essential to mining operations. They must be safe and reliable to carry tons of ore, people and equipment in and out of the mines, and often reaching startling depths underground.

Modern mine hoists are complex systems which require detailed knowledge of drives, control engineering and also electrical, pneumatic and hydraulic systems. Such breadth of knowledge is the basis of the North American team’s success.

In Canada, Klaus was influential in developing the hoist systems for a mine in Northern Quebec that is 2,250 meters deep (7,380 feet – the deepest shaft in Northern Hemisphere). That is by no means the deepest in the world - the East Rand gold mine in South Africa is more than 3,500 meters deep (more than 11,000 feet).

Klaus began his career as a foreman in a coal mine in Poland in 1968, and after two years set up an automation centre for Polish coal mines which grew to employ more than 50 qualified engineers and technicians. Later, he began developing new control systems, principally for mine hoists.

He moved to Nigeria in 1979 to teach at Kaduna Polytechnic, then joined Asea in South Africa in 1982 and established a mine hoist team. That team developed unique hoist systems that were later adopted throughout ABB.

More than 30 patents

He has developed systems for mines all over the world, and in 39 years of professional experience his R&D work has resulted in more than than 30 patents.

"Every hoist is different," he said, "and ABB’s strength is knowing how to adapt our equipment and systems to the different mechanical and electrical requirements of different hoists."

Teamwork is essential in view of extremely complex modern hoisting systems, Klaus added. "I am very proud of our mining team. Almost all of our mine hoist engineers were either hired or trained by me, and in my opinion and the opinion of our customers, it is the best team in North America."[/COLOR]

網站客服

網站客服 粵公網安備 44030402000946號

粵公網安備 44030402000946號